Bioworks Verfahrenstechnik GmbH

Booth number: HALL 4 - 4B45

www.bioworks-gmbh.de/en/home.html

About us

BIOWORKS® Verfahrenstechnik GmbH offers complete process solutions for wastewater treatment, combining German engineering with decades of global project experience. The company develops and manufactures different highly efficient electro-mechanical equipment, as well as providing different technologies ensuring sustainable and reliable wastewater treatment. BIOWORKS® also provides consultancy, training, and after-sales service to support municipalities and industries worldwide.

Address

Wernher-von-Braun-Straße 9

85640 Putzbrunn

Germany

E-mail: a.macarov@bioworks-gmbh.de

Phone: +49 451519560

Internet: www.bioworks-gmbh.de/en/home.html

Contact person:

Malek Youssef

Technical Sales Engineer

E-mail: m.youssef@bioworks-gmbh.de

Phone: +49 45151 956-53

Products & Services

BIOWORKS® Verfahrenstechnik GmbH develops and manufactures highly efficient electro-mechanical equipment that ensures high quality treatment of wastewater in different treatment stages.

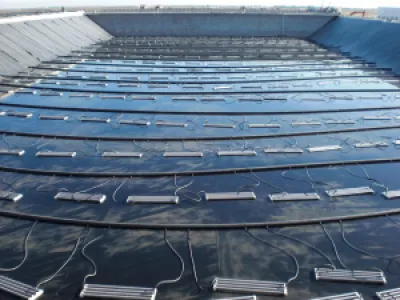

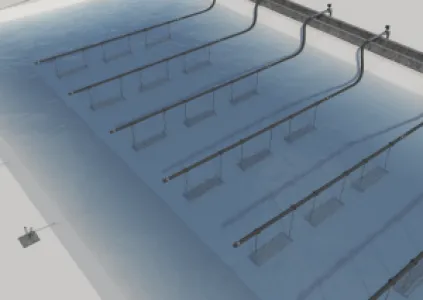

OXIWORKS® and OXIRISE®

OXIWORKS® is a floating fine-bubble aeration system designed for energy-efficient oxygen transfer in activated sludge and lagoon applications. Its self-propelled motion ensures optimal oxygen distribution and significant energy savings compared to fixed aeration systems.

The optional OXIRISE® system enables convenient inspection and maintenance under full operation by automatically lifting diffusers to the surface.

Together, these innovations deliver efficient aeration, simplified maintenance, and long-term operational reliability in wastewater treatment processes.

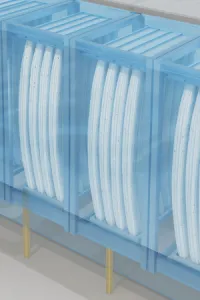

WAVEWORKS

WAVEWORKS cassette modules use high-performance PVDF hollow-fiber membranes for advanced filtration in wastewater and water treatment applications. The membrane structure, reinforced with a PET braid, provides excellent strength, durability, and permeability. With a pore size of 0.1 µm, WAVEWORKS ensures high-quality effluent and reliable long-term operation, making it ideal for MBR and tertiary filtration processes.

DISKWORKS C

DISKWORKS is a high-performance pile cloth filtration unit designed for advanced solid–liquid separation in municipal and industrial water and wastewater treatment. It integrates the GDisk® filter for efficient removal of suspended solids and phosphorus in primary, tertiary, and quaternary treatment stages.

The system operates through gravity-driven filtration, ensuring low energy consumption, while the polyester pile cloth media provide deep filtration and reliable performance. Automated backwashing and sludge discharge maintain continuous operation and reduce maintenance. Compact, fully submerged installation options in stainless steel or concrete tanks make DISKWORKS ideal for retrofitting or new plant designs.

SKIMWORKS

SKIMWORKS is an automated floating sludge suction system designed for secondary clarifiers in wastewater treatment plants. It efficiently removes floating sludge and scum using a self-adjusting circular weir that adapts to changing water levels.

The system operates automatically based on timed and position-based control, ensuring precise sludge removal with minimal supervision. A built-in backflush function and dry-run protection guarantee reliable performance and low maintenance. SKIMWORKS offers easy installation, energy-efficient operation, and high removal efficiency — ideal for municipal and industrial applications as well as other water management systems.

CLARIWORKS S

CLARIWORKS S is an integrated rectangular clarifier system designed for secondary settling in wastewater treatment plants. Installed directly at the end of the activated sludge basin, it combines efficient sludge removal with a compact footprint and reduced overall investment cost.

The system features a travelling scraper bridge and stainless-steel suction tubes for continuous sludge extraction via the siphon principle, ensuring stable operation and high treatment performance. Maintenance can be performed while the tank remains filled, minimizing downtime. The modular design allows flexible sizing for flow rates from 150 to 1,500 m³/h and enables easy transport and installation in standard containers.

(2)-thumb.webp)